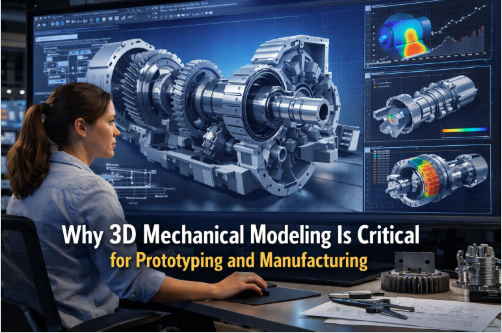

Prototyping and manufacturing are the processes by which the designs of the products are compared with reality. The designs should be able to transit from the ideal world to the real world while meeting the tough requirements of accuracy, functionality, and cost-effectiveness.

The errors that are generated in this process are mostly costly and time-consuming to correct. This is why 3D mechanical modeling has become an important part of the prototyping and manufacturing process.

Bridging the Gap Between Design and Physical Prototypes

Digital models are the connection between ideas and physical prototypes that set some dimensions, tolerances, and mechanical relationships before anything is made.

The digital models that possess the capability to represent the design accurately ensure that the prototypes have the required design from the very start. This reduces the need for trial-and-error procedures and enables the team to focus on the validation of performance by prototypes instead of basic design parameters.

Decreasing Prototype Cycles and Expenditures

Physical prototypes are expensive. This is because all the phases of the prototype will require materials, labor, and time. In some cases where the designs have not been validated, more than one prototype may be required before the fit problems are solved.

Thus, through verification of geometry and assemblies, it is possible to reduce the number of prototypes that have to be developed.

Improving Fit, Form, and Function Validation

A prototype should also ensure that the components are compatible with each other. Digital models allow engineers to check the compatibility of the components before they actually build them.

Engineers can analyze the functionality of assemblies, motion, and loads using 3D mechanical modeling. This enables prototypes to be more than mere exercises in basic correction.

Supporting Manufacturability from the Start

A design may be theoretically possible but difficult to manufacture. Manufacturing constraints such as tool availability, machining ability, assembly sequence, and material properties should be considered from the early stages of design.

Digital models help engineers evaluate manufacturability and design intent. In this regard, the limitations of manufacturing can be overcome in modeling, and there will be no last-minute changes in the design, which can be costly.

Streamlining Communication Between Teams

Prototyping and manufacturing activities should be done in a synchronized manner by design engineers, manufacturers, suppliers, and quality teams. There should be appropriate communication to prevent any misunderstanding of specifications.

The digital twin, as the single source of truth, can be accessed by all teams. Feasibility studies can be carried out by the manufacturers, the quality teams can define the standards of inspection, and the suppliers can plan their production accordingly.

Quality Control

The product should have the same quality in all the manufactured products. Digital models are very accurate references that are useful in inspection and measurement.

When prototypes and finished products are produced from the same accurate digital information, there is less variation. This is significant because it ensures that quality standards are maintained and that defective merchandise does not reach the consumer.

Supporting Advanced Manufacturing Techniques

The current manufacturing industry is gradually accepting new technologies such as CNC machining, 3D printing, and automated assembly. These technologies need accurate digital data to function effectively.

The most effective models are fully integrated with manufacturing systems, and this ensures that tooling paths, print parameters, and assembly processes are all based on the correct geometry.

Managing Complexity in Modern Products

As products become more complex, with tighter tolerances and more components, the likelihood of errors being introduced during the manufacturing process also increases. Digital modeling can help with the management of product complexity by modeling the interaction of the components in an assembly.

Scaling Production with Outside Help

Because of the growing demands for development, there could also be a need for more modeling skills in the teams. Some companies may choose to work with a 3D game art outsourcing studio to complement their workforce, especially in detailed modeling.

Though these studios have always been linked with the entertainment industry, they could have offered a lot in terms of modeling detail and scalable processes that could have been of immense use in prototyping and manufacturing if they had been developed on the basis of engineering specifications.

Long-Term Value Beyond Initial Production

Digital models are still relevant even after the commencement of production. Digital models assist in maintenance, upgrades, and product updates. Digital models assist in problem-solving, upgrades, or expanding production based on accurate models. This is a long-term usability factor that ensures the investment in digital modeling will continue to pay off throughout the product life cycle.

Conclusion

Prototyping and manufacturing are processes that demand accuracy, efficiency, and reliability throughout the process. 3D mechanical modeling is a very important factor in this context, as it reduces errors and costs, and also improves teamwork. It assists organizations in producing quality products quickly with minimum risks. Whether it is done in-house or with the assistance of a good 3D game art outsourcing firm, it is very important to invest in good modeling processes for successful prototyping and manufacturing in today’s competitive world.