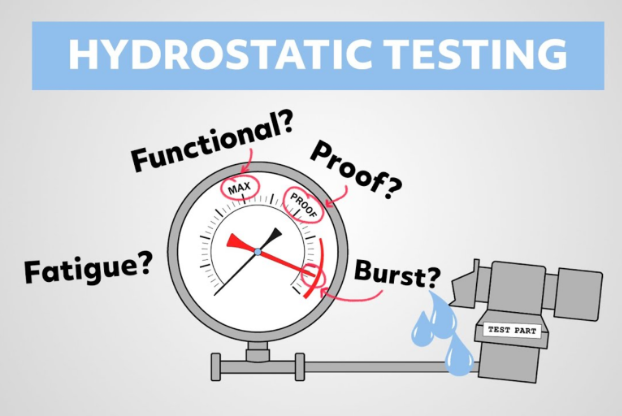

When assessing the structural integrity of pipes, tanks, and pressure vessels, one of the most reliable methods used across industries is hydrostatic pressure testing. This process involves filling the equipment with water or another incompressible fluid, then pressurising it to a predetermined level to ensure it can safely withstand its operational demands. By identifying leaks, weaknesses, or material defects, this rigorous form of non-destructive testing plays a crucial role in maintaining safety standards in sectors such as oil and gas, chemical processing, and water utilities. Regular testing not only helps prevent costly failures but also supports regulatory compliance and enhances long-term asset reliability.

At Armfield, we understand the critical role hydrostatic pressure testing plays in safeguarding infrastructure and lives. With decades of experience in engineering education and industrial-grade equipment design, our solutions offer precise, dependable methods for understanding and applying pressure-based performance analysis. Whether you’re an educator, researcher, or industry engineer, our range of products supports robust testing and fluid mechanics education from the ground up.

What is Hydrostatic Pressure Testing and Why is It Important?

Hydrostatic pressure testing is a vital non-destructive testing (NDT) method designed to confirm the strength and leak resistance of pressure-retaining components. It involves completely filling the vessel or pipeline with water (or an equivalent fluid), purging all air, and applying pressure above the operational limit. Any loss in pressure or signs of leakage indicate a problem.

This process not only identifies immediate faults—such as hairline cracks or joint weaknesses—but also uncovers latent issues that could worsen under normal operational pressures. In industries where the consequences of failure could be catastrophic—think chemical plants, petroleum pipelines, or municipal water systems—such rigorous checks are not optional; they’re a necessity.

Industries That Rely on Hydrostatic Pressure Testing

When assessing the structural integrity of pipes, tanks, and pressure vessels, hydrostatic pressure testing is often mandated by engineering standards and regulatory frameworks. Key sectors relying on this method include:

- Oil and Gas: Pipelines and pressure vessels must be tested to prevent environmental disasters and human casualties.

- Chemical Processing: Equipment handling corrosive materials is prone to wear; regular testing ensures containment and process reliability.

- Water Utilities: Ensures pipe networks are leak-free before being placed into service or after repairs.

- Pharmaceutical & Food Processing: Sterile environments require equipment integrity to maintain safety and quality.

- Construction and Civil Engineering: Used in testing HVAC systems, water mains, and large structural tanks.

In all these sectors, hydrostatic pressure testing proves essential to operational success and safety. That’s where Armfield comes in—with purpose-built equipment and educational tools that bring this critical process to life.

Armfield’s Expertise in Hydrostatic Pressure Testing

As an employee of Armfield, I take pride in how our solutions have consistently supported both academic and industrial applications of hydrostatic principles. Our fluid mechanics product range is uniquely designed to help users visualise, measure, and understand how pressure behaves under controlled test conditions.

Our F1-10 Hydrostatics Bench is a cornerstone apparatus in many engineering labs worldwide. While it is primarily designed to study fundamental fluid properties, the principles it demonstrates directly relate to real-world hydrostatic pressure testing scenarios. Through this hands-on experience, students and professionals alike can understand what happens when assessing the structural integrity of pipes, tanks, and pressure vessels.

In more advanced contexts, our pressure and flow measurement tools offer the precision and durability needed for industrial-level testing and experimentation. We’ve worked closely with universities and engineering firms across the globe to refine these systems, ensuring they meet both educational goals and regulatory expectations.

The Armfield Advantage

There’s a reason our name is trusted across over 100 countries. Our approach to hydrostatic pressure testing solutions is guided by three core principles:

1. Accuracy

We ensure that every pressure reading and experimental output from our systems reflects real-world conditions. Whether testing a pressure vessel or simulating pipe stress, the data is reliable and replicable.

2. Durability

Our equipment is made in the UK using robust, high-quality materials. This guarantees long-lasting performance, even in rigorous lab or field conditions.

3. Educational Value

Our teaching modules and manuals don’t just answer what is hydrostatic pressure testing—they teach users how to apply it, troubleshoot systems, and draw real conclusions from data.

Our goal at Armfield is not just to deliver tools, but to empower the engineers, technicians, and safety inspectors of tomorrow. We make it easier to perform and understand what happens when assessing the structural integrity of pipes, tanks, and pressure vessels, not just in theory but in practice.

Safety, Compliance, and Reliability—Backed by Armfield

The cost of structural failure can be enormous, both financially and in terms of human safety. That’s why hydrostatic pressure testing is so critical—and why having the right testing equipment matters.

At Armfield, we are proud to be a partner in safety, education, and innovation. By offering world-class systems to teach and perform this crucial method, we help organisations meet safety regulations, avoid downtime, and increase the reliability of their assets.

When assessing the structural integrity of pipes, tanks, and pressure vessels, one of the most reliable methods used across industries is hydrostatic pressure testing, and Armfield is your trusted ally in delivering accurate, insightful, and compliant testing solutions.

Ready to Improve Your Testing Capabilities?

If you’re looking to enhance your understanding or implementation of hydrostatic pressure testing, Armfield offers the expertise and equipment to support your goals.

👉 Contact us today to learn more about our pressure testing equipment, educational resources, and tailored solutions for your industry.

Let’s work together to build a safer, smarter future—one test at a time.